What is 5S lean

In today's fast-changing world, efficiency is a crucial factor for success. Companies are constantly striving to streamline processes, reduce costs and improve quality. One of the most effective methods to achieve this is the implementation of 5S Lean. But what exactly does 5S Lean entail?

5S Lean is a systematic method for workplace organisation that originated in Japan. It is part of the broader Lean Manufacturing principle, which aims to eliminate waste and optimise productivity. The name 5S refers to five Japanese words, each representing an aspect of workplace organisation:

- Seiri (Sorting): Separating necessary and unnecessary items.

- Seiton (Systematise): Arranging items so that they are easily accessible.

- Seiso (Cleaning): Cleaning the workplace to quickly identify problems.

- Seiketsu (Standardising): Standardising processes and procedures.

- Shitsuke (Sustain): Maintaining and improving 5S standards.

(1) Seiri (Sorting).

The first step in 5S Lean is Seiri, which translates to "sorting". The purpose of this step is to distinguish between what is essential to the work process and what is not. It involves removing unnecessary items that take up space and cause confusion.

- Assess workstation: Inspect every corner of the workstation to make a list of all items present.

- Categorise: Divide items into categories such as necessary, rarely used and unnecessary.

- Remove: Remove unnecessary items from the workstation. This could mean throwing them away, recycling or storing them in another location.

Removing unnecessary items creates more space. This increases efficiency, as workers can better focus on essential tasks without distractions. It also improves safety, as less clutter reduces the risk of accidents.

(2) Seiton (Systematising)

The second step is Seiton, which means "systematising" or "organising". After the unnecessary items have been removed, it is time to organise the necessary items in a way that is efficient and logical.

- Analyse workflows: Understand workflows and the order in which tasks are performed.

- Organise the workplace: Place items in a way that supports the workflow. For example, tools that are used frequently should be within easy reach.

- Labelling and marking: Use labels, colours and markers to identify items and mark their locations.

This gives workers faster access to what they need, reducing time wasted searching. This leads to improved efficiency, as an organised workplace supports a smooth and efficient workflow.

(3) Seiso (Cleaning)

The third step is Seiso, which means "cleaning". This goes beyond superficial cleaning; it includes thorough cleaning of the workplace to identify and resolve any problems quickly.

- Daily cleaning routines: Set daily cleaning routines for all employees.

- Inspections: Conduct regular inspections to ensure the workplace remains clean and to identify problems.

- Maintenance: Ensure maintenance of equipment and tools to keep them in good condition.

A clean workplace promotes employee health and safety and helps identify wear and tear or defects early. Moreover, a clean environment contributes to a positive work atmosphere and increased morale.

(4) Seiketsu (standardise)

The fourth step is Seiketsu, which means "standardise". This involves standardising the best practices from the previous steps to ensure consistency and sustainability.

- Documentation: Document best practices and procedures for sorting, organising and cleaning.

- Train: Train employees in these standardised procedures.

- Audit and feedback: Conduct regular audits to check compliance and collect feedback to promote continuous improvement.

Standardisation ensures consistent performance and quality, so employees know exactly what is expected of them and how to perform their tasks. Continuous audits and feedback also encourage continuous improvement of processes.

(5) Shitsuke (Sustain)

The fifth and final step is Shitsuke, which means "sustain". This is about maintaining standards and ensuring that the 5S methodology becomes a permanent part of the corporate culture.

- Culture of discipline: Promote a culture of discipline and accountability.

- Motivation and commitment: Ensure that all employees are involved and motivated to adhere to the 5S principles.

- Continuous improvement: Encourage a culture of continuous improvement, where employees are always looking for ways to improve the workplace.

5s Workplace organisation

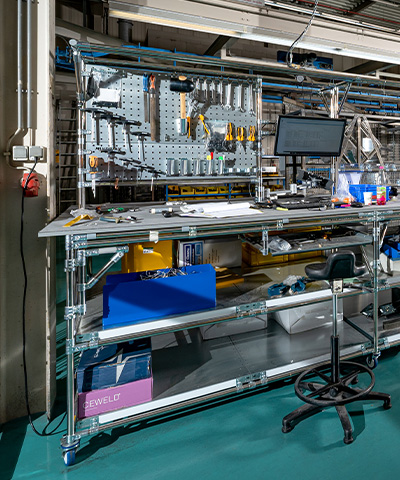

The use of workbenches and height adjustable workbenches, plays a crucial role in workplace organisation. Work tables provide an orderly and ergonomic space for employees to perform their tasks. Adjustable work tables can be adjusted to the needs of individual workers, which promotes comfort and efficiency and contributes to a healthy working posture.

Besides work tables, it is also important to add shelves, holders and hooks to your workplace. These ensure that materials and tools are kept in a structured manner and easily accessible, allowing workers to perform their tasks effectively without wasting time searching for supplies.

By applying the principles of 5S and using work tables and other organisational tools effectively, organisations can create an organised, efficient and safe working environment. This not only contributes to improved productivity, but also to employee satisfaction and well-being, which in turn improves the overall performance of the organisation.

Implementation of 5S Lean

Implementing 5S Lean requires careful planning, dedication and perseverance. It starts with understanding the current situation and setting clear goals and expectations. Extensive training for all employees on the 5S principles and their benefits is essential. A pilot project is then launched in a specific area to gain experience and demonstrate success. Once the pilot project is successful, the 5S methodology is rolled out across the organisation, with ongoing monitoring and adjustments. Support and feedback are crucial during this process to improve and refine the implementation.

Benefits of 5S

The benefits of implementing 5S Lean are numerous and contribute to both the short-term and long-term successes of an organisation. Some of the key benefits include:

- Improved efficiency: By removing clutter and organising the workplace, tasks can be completed faster and more efficiently.

- Higher quality: An organised and clean workplace reduces the likelihood of errors and defects.

- Increased safety: Less clutter and a better organised workplace reduce the risk of accidents and injuries.

- Better morale: Employees appreciate a clean, organised and safe workplace, which contributes to higher satisfaction and morale.

- Cost effectiveness: By reducing waste and increasing efficiency, companies can reduce costs and improve profit margins.

Interested in a 5S workplace?

Implementing 5S may initially take time and dedication, but the benefits to your organisation are undeniable. An organised and tidy workplace minimises waste and maximises productivity and safety. Are you ready to unlock the potential of your workplace? We would love to help you!

Feel free to contact us for more information.